HEUI Fuel Injection - Technical Issues

FORD POWER STROKE 6.0-L AND 7.3-L ENGINES:

HEUI INJECTOR PROBLEMS EXPLAINED

The Causes And The Solution

Both the Ford Powerstroke 6.0-L and 7.3-L engines are known to experience cold start or injector stiction issues. The 7.3-L was produced between 1994 and 2003, while the 6.0-L was produced between 2003 and 2007. Both engines were actually manufactured by Navistar International and incorporated the HEUI injector system. Engine stiction or cold start issues are in fact more prevalant and often more serious in the 6.0-L version.

Hydraulic electronic unit injector (HEUI) type fuel injectors were commonly used in many medium-duty truck models for many years. In part, because of the issues with stiction and the failure rate of the HEUI fuel injectors, Ford discontinued their use in 2008, and changed to the most widely used fuel injection system to date, the peizo ceramic electronic injector. Peizo ceramic electronic injectors overcame the problems inherent in the design of HEUI fuel injectors.

Since its disappointment with the performance of the 6.0-L engine, Ford discontinued its relationship with Navistar International finally in 2010. Since 2011, the Ford Powerstroke engine is made in-house by Ford.

What makes the Ford Power Stroke 6.0-L engine more prone to injector issues? What can be done about it?

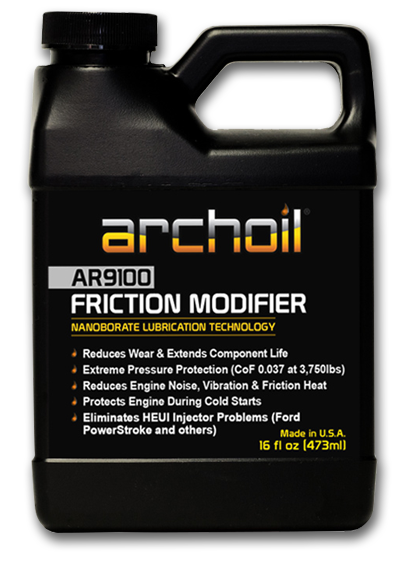

Failure in the HEUI injection system of the 6.0-L engine is caused by multiple factors. Use of Archoil’s AR9100 Nanoborate Friction Modifier can help to overcome these problems:

- The 6.0-L engine runs the high-pressure engine oil system at almost twice the pressure of the 7.3-L Powerstroke engines. With hard acceleration, "4000 psi" in the 6.0-L engine is achieved instantly. This causes great wear on the motor oil; the oil molecules are sheared, and the base long- and short-chain polymers of the oil are reduced and rendered ineffective in a short period of time. In effect, the oil is broken down and reduced to a thinner grade in a short amount of time in the 6.0-L engine.

- The 6.0-L injector is more complex than the one used in the 7.3-L engine. Whereas the 7.3-L engine uses only 1 coil to open the injector, and a simple return spring to close it, the 6.0-L injector includes more sophisticated parts, which make it capable of much faster reaction times to changing conditions or commands from the engine electronics. In the 6.0-L HEUI injector are 2 internal electric coils that operate the opening and closing of the injector fuel flow through the spool valve, with a range of motion of less than half a millimeter. Because the fuel flowing through the 6.0-L fuel injector includes a mixture of the motor oil, the broken down and thinner-grade oil resulting from use in a 6.0-L engine, and oil contaminants which are a product of movement through any engine over time, greatly affect the minute operation of the spool valves. Thus, the more sophisticated parts that make the injector system in the 6.0-L Powerstroke capable of greatly improved performance over the 7.3-L engine, are greatly affected by even the most minor flaw, which can have a major effect on their expected efficient operation; this impeded motion is called ‘stiction,’ or ‘sticking’ -- not moving freely as commanded.

- The minute movements of the spool valves accommodate a range of 700-4000 psi oil pressure, changes which can occur in a short amount of time. The spool valve needs to be clean, smooth, and slippery as it operates within a very small orifice. Especially when the oil is cold, it does not flow as easily through the injector, and this or any contamination can cause the valve to get stuck because of free-play wear of the valve or side-loading, and result in what is called “stiction.”

- The 6.0-L engine has an extremely high-pressure engine oil system which uses a separate high-pressure oil pump (HPOP) to pressurize the fuel within the fuel injector for proper atomization and direct injection into the cylinders. With reduced function of the oil in the 6.0-L engine, the efficiency of the HPOP and its output are negatively affected.

- It is quite plausible that, with normal operation of the HEUI injection systems in the 6.0-L engines, which break motor oil down on a molecular level, that heat and thus varnish build-up are generated. The most intricate parts movement of the spool valves and operations of the HPOP are negatively affected by this build-up.

AR9100 Nanoborate Friction Modifier alleviates the problems due to oil breakdown, varnish build-up, stiction of the spool valves, decreased efficiency of the HPOP, and the resultant decreased performance of the 6.0-L and the older 7.3-L Ford Powerstroke engines. AR9100 Nanoborate Friction Modifier reduces friction, dissolves carbon and varnish deposits, enhances the lubricant qualities of oil, and increases fuel efficiency of the Powerstroke, or, actually, any mechanical engine or system.